Induction Hardening Surgical Knife Blades

Views Send Enquiry

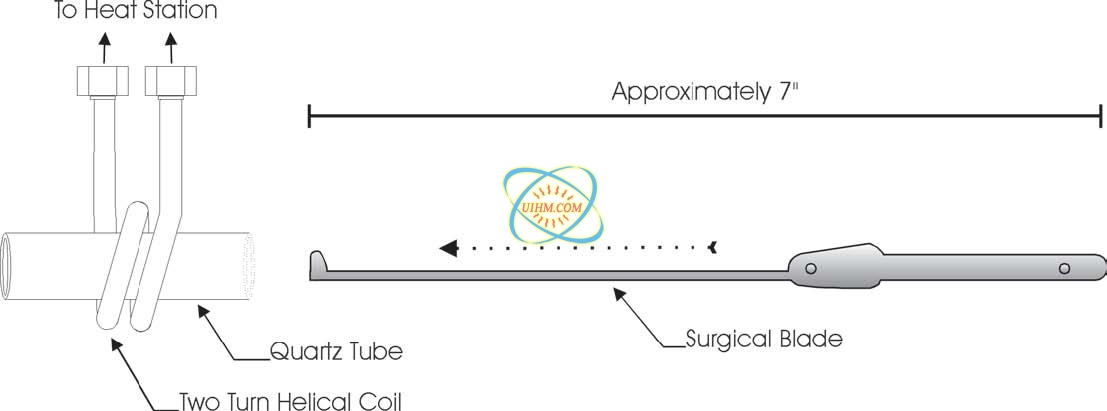

Objective Harden a 4″(101.6mm) section of a Stainless Steel surgical blade measuring 7″ (177.8mm) long. Hardness should be 48 to 53 Rockwell C on the blade after processing.

Material 420 Stainless Steel Surgical Blades measuring 7″(177.8mm)

long, 1/4″(6.35mm) wide at the shank, and 0.085″ (2.2mm)

thick at the blade.

Temperature 1850ºF(1010ºC)

Frequency 365 kHz

Equipment •Power of 4.5 kW induction heating system equipped with a remote workhead including one (1) capacitor equaling 1.2 μF

• An induction heating coil designed and developed specifically for this application.

Process A two turn helical coil with an internal quartz tube designed to scan the length of the blade is used to heat the blade to 1850ºF (1010ºC) to achieve the desired hardness.

Results/Benefits Induction heating provides:

• Flameless process

• Improved production rate

• Consistent & repeatable results

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction hardening axle (shaft) by 100KW induction heater

induction quenching axle (shaft) by 160KW induction heater

induction hardening inner surface (inwall)

Induction Hardening Harvestor Combined Finger

Induction Hardening Harvestor Combined Blade

workpiece for induction hardening

induction hardening veterinary instrument

induction hardening surgical device

Newest Comment

No Comment

Post Comment