-

Keywords"surface",total

70 records

-

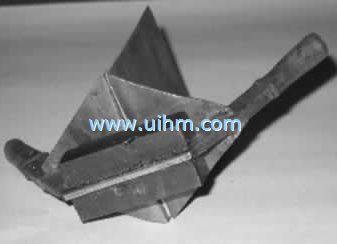

flat shape induction coil for surface heating-1

custom build induction coils for different applications flat shape induction coil for surface heating-1Base Induction Coil Design and Theory Induction Coil Design and Fabrication

-

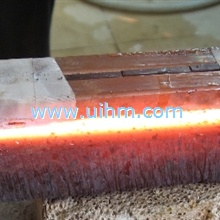

custom build induction for heating surface of steel plate

custom build induction for heating surface of steel plate_1 custom build induction for heating surface of steel plate_2 Base Induction Coil Design and Theory Induction Coil Design and Fabrication

-

flat induction coil for surface heating treatment

flat induction coil for surface heating treatment flat induction coil for surface heating treatment

-

induction surface quenching works

Induction quenching is the process of quenching steel by heating it. It is done by an alternating magnetic field to a temperature above or within a specific transformation range. It is straight away followed by quenching. This procedure of quenching can be…

-

effect of surface hardening by induction heating

Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of the spe…

-

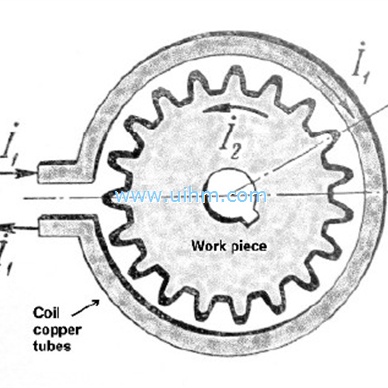

induction surface hardening

Kelvin Effect, Mean Curvatures and Load Impedance in Surface Induction Hardening: An Analytical Approach including Magnetic Losses Abstract– Kelvin effect(Skin effect) is used in surface hardening produced by induction heating of gears, cam forms, camsh…

-

induction heating for surface triggering styrene polymerization

Titanium and its alloys present high interests for technological applications due to their high resistance corrosion, mechanical properties and biocompatibility [1-5]. For example, titanium is largely used as orthopedic metallic implant [6]. In addition, T…

-

surface hardening of steels

Selective hardening is applied because of one or more of the following reasons:(1) Parts to be heat-treated are so large that conventional furnace heating and quenching becomeimpractical and uneconomical - examples are large gears, large rolls and dies;(2)…

-

induction surface hardening of steel

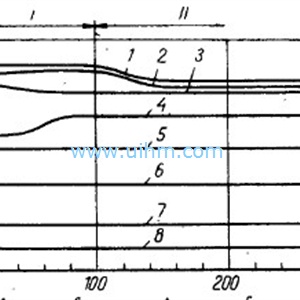

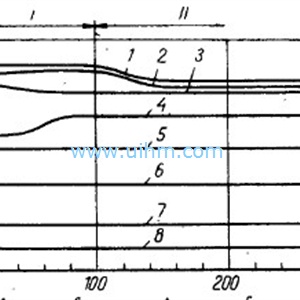

High-level surface heating of a thermo technically massive body, when the cooling of the surface to be hardened happens due to abstraction of heat into the body so that the hardening medium is not required, is of both practical and theoretical interest. Ti…

-

effect of surface hardening by high frequency induction heating

Surface hardening of carbon steel by high frequency induction heating (HFIH) produces a considerable increase in its resistance to stress corrosion [1, 2]. The magnitude of this increase depends on the depth of surface hardening, on the strength of the spe…