Induction Brazing Steel Fitting

Views Send Enquiry

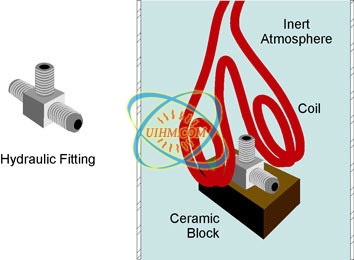

Objective To heat a steel hydraulic hose fitting in an inert atmosphere to 2200°F within 7 seconds for brazing without any carbon buildup.

Material Three-opening steel hydraulic fitting, pure copper braze paste

Temperature 2200°F

Frequency 273 kHz

Equipment Power of 6 kW, remote heat station containing one 1.0 μF capacitor and a specially designed induction coil.

Process A specially designed, four-turn split helical coil was used to provide optimal heating to the joint area of the hydraulic fitting.

The testing was done in the ABS Mark 2 containing a mixture of 95% Argon and 5% Hydrogen gas. RF power of 6kW heated the steel assemblies to 2200°F within 7 seconds. An infrared pyrometer was used to measure the temperature of the part. After the copper braze flowed, the parts were allowed to cool and were removed from the bell jar. Results Successful results were achieved at 2200°F within 7 seconds.

The copper braze material flowed well and the joints were clean. For this type of brazing, the size of the power supply is dependent on the desired time-to-temperature

Material Three-opening steel hydraulic fitting, pure copper braze paste

Temperature 2200°F

Frequency 273 kHz

Equipment Power of 6 kW, remote heat station containing one 1.0 μF capacitor and a specially designed induction coil.

Process A specially designed, four-turn split helical coil was used to provide optimal heating to the joint area of the hydraulic fitting.

The testing was done in the ABS Mark 2 containing a mixture of 95% Argon and 5% Hydrogen gas. RF power of 6kW heated the steel assemblies to 2200°F within 7 seconds. An infrared pyrometer was used to measure the temperature of the part. After the copper braze flowed, the parts were allowed to cool and were removed from the bell jar. Results Successful results were achieved at 2200°F within 7 seconds.

The copper braze material flowed well and the joints were clean. For this type of brazing, the size of the power supply is dependent on the desired time-to-temperature

Next: Induction Brazing Turbine BladesPrevious: Induction Brazing Steel Conduit

Good

Bad

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Newest Comment

No Comment

Post Comment